I have seen the benefit that S&OP (Sales and Operations Planning) offers to an organisation if done correctly. I have also seen them fail. The process is robust, but how it is implemented and an organisation’s unwillingness to change, can lead to failure.

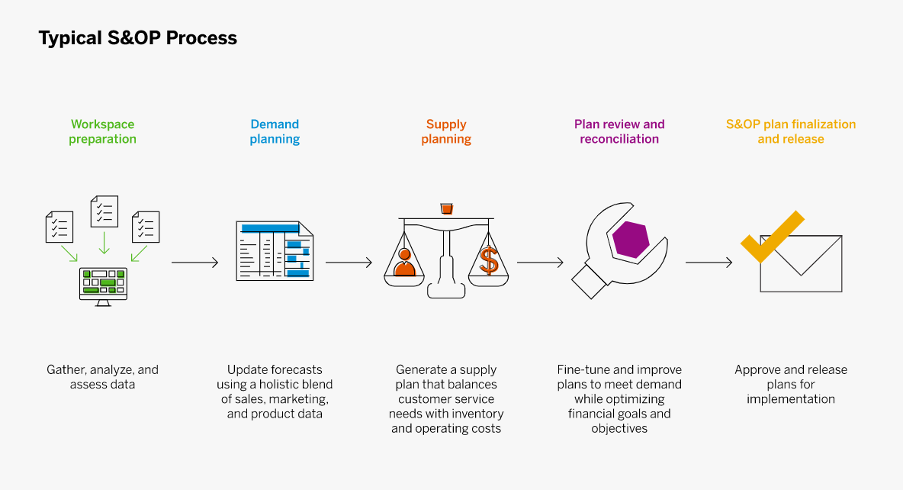

S&OP also known as Sales and Operations Planning, is an Integrated Business Management (IBM) process that drives organisational unity bringing balance to supply and demand. It aligns multiple operational areas in the business and allows for strategic targets to be monitored, reported, and met. In a volatile market with supply chain disruptions, it is more important now than ever to ensure that S&OP delivers an updated integrated operational plan, whilst making the supply of products more resilient. Below is a typical process that most follow, however, it is important that this is tailored to your own business.

What’s in it for me:

There are several direct benefits to having a collaborative process in your businesses. Imagine Sales, Marketing, Supply Chain, Operations and Finance all working from one number, the same number. Imagine your NPD being on time and not a surprise to those who must manufacture it. Imagine reducing your working capital, reducing the time spent in meetings and your senior team aware of what the plan looks like for the next 18-36 months. It sounds a little hard to believe, but all very possible if done right!

The data gives insight into what customers are buying and when which lowers inventory and reduces waste. Also, it gives your business better visibility to enable you to make better decisions, with day-to-day feedback and support. Along with the benefit of a shorter planning process as S&OP adds structure to the planning process. Communication can always be a difficult task across departments with differing schedules and functions, S&OP eliminates departmental silos, as it creates consensus as everyone works towards to same goals and timeframes. Finally, the benefit of a seamless feedback loop, with systematic reporting in place to ensure teams can rapidly address any issues or misalignment.

Choosing the right tools:

The first thing to mention here is that many businesses already have a sales and operations planning tool, however, in my experience, it can sometimes be the right tool but is utilised incorrectly and just helps to drive inefficiencies. Therefore, some organisations don’t see the benefit as it is not driving significant returns on investment.

S&OP solutions integrate real-time data, including user behaviour and market-related information, which allows for supply and demand changes to be managed day-to-day – the short-term horizon. Things change daily not monthly! Selecting the right ERP is critical.

One of the biggest reasons for S&OP failure, was the lack of buy-in from the C-Suite, ‘It’s a supply chain process’, ‘isn’t that your job’. S&OP is not a supply chain process; it is in fact a sales process, it drives revenue makes you more efficient and cuts out any second guessing.

“The business was turned around as a direct result of this project. Budgeted monthly sales targets have been achieved or exceeded for 6 consecutive months. Amongst many other delivered enhancements”.

If you want some advice on your current process, feel free to get in touch for an impartial discussion.